Bolt grades are the industry’s way of classifying fasteners by strength, durability, and recommended applications. Whether you’re assembling furniture, building a deck, or working on automotive repairs, understanding bolt grades ensures you pick the perfect bolt for the job. In this guide, we’ll break down the essentials of bolt grades/ baut, explain common classifications, and share practical tips to help you secure materials safely and efficiently.

Understanding Bolt Grades

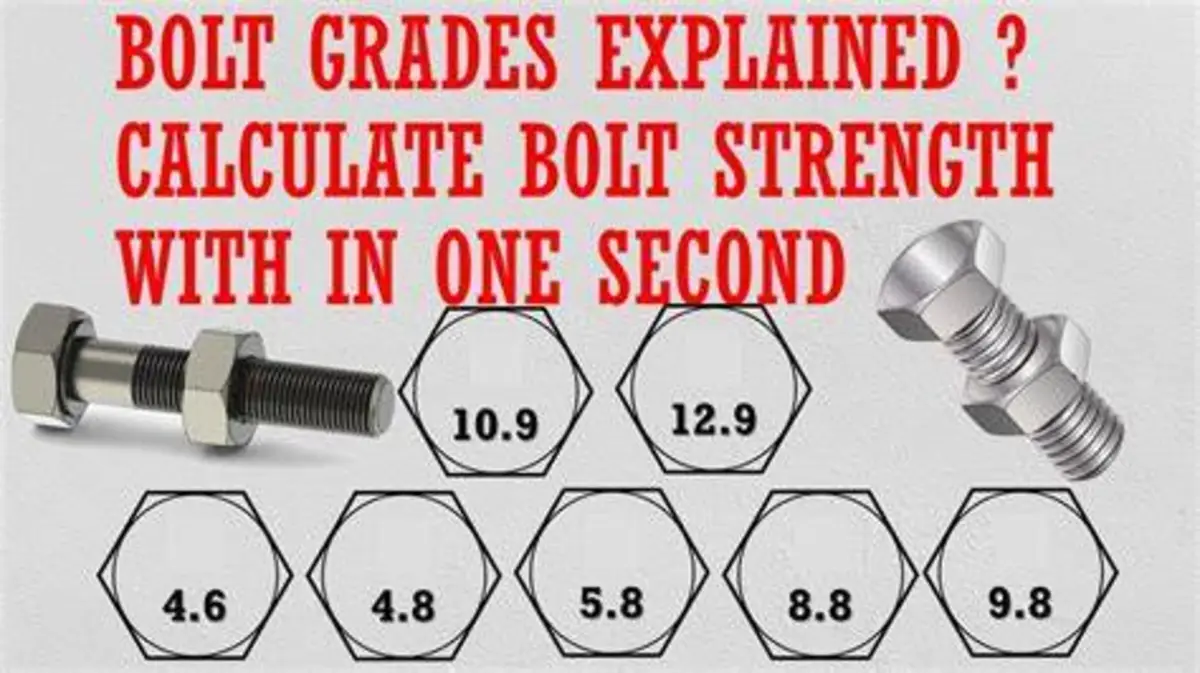

Bolt grades are standardized markings that tell you about the tensile strength and material properties of a bolt. In the United States, grades 2, 5, and 8 are most common. Metric bolts use classes like 8.8, 10.9, and 12.9. The higher the grade or class, the greater the tensile strength. This system lets you match bolts to load requirements, environmental conditions, and safety margins, ensuring your structure or machinery performs reliably under stress.

Common Bolt Grades and Their Applications

When you shop for bolts, you’ll usually see grade stamps on the head. Here’s a quick overview of popular grades and where they shine:

| Bolt Grade | Tensile Strength (psi) | Typical Uses |

|---|---|---|

| Grade 2 | 74,000 | Light-duty carpentry, wood projects |

| Grade 5 | 120,000 | Automotive, machinery, structural |

| Grade 8 | 150,000 | Heavy machinery, high-stress joints |

| Class 8.8 | 800 MPa | European automotive, bike frames |

| Class 10.9 | 1,040 MPa | High-performance engines, railways |

Choosing between these depends on the forces your bolt must resist. For example, a residential deck might work with Grade 5, while a suspension component in a car demands Grade 8 or Class 10.9.

How Bolt Grades Are Marked

Bolt heads carry simple symbols to denote their grade:

US Grades: Two radial lines (Grade 5) or six lines (Grade 8) stamped on the head.

Metric Classes: Numeric codes like “8.8” or “12.9” cast directly into the metal.

These head stamps let you verify strength without cutting into the bolt. Always inspect bolts for clear, legible marks before installation. Faded or missing stamps could indicate substandard or counterfeit fasteners.

Factors to Consider When Choosing Bolt Grades

Selecting the correct bolt grade involves more than just strength. Keep these factors in mind:

- Load Requirements: Calculate static and dynamic loads to ensure the bolt’s tensile rating exceeds the expected force.

- Environmental Conditions: Corrosive environments (saltwater, chemicals) call for stainless steel or coated high-grade bolts.

- Material Compatibility: Match bolt material to the components you’re joining to prevent galvanic corrosion.

- Safety Margin: Always choose a bolt grade that offers at least a 25–50% safety buffer above calculated loads.

- Cost vs. Performance: Higher-grade bolts cost more, so balance budget constraints against critical performance needs.

Tips for Selecting and Installing Bolt Grades

- Inspect Packaging and Stamps: Buy bolts from reputable suppliers; confirm grade markings before use.

- Torque Specifications: Follow manufacturer torque charts—over- or under-tightening can compromise bolt integrity.

- Use Washers and Locking Devices: Flat washers distribute load; lock washers or thread-lock compounds prevent loosening.

- Keep Spares on Hand: Store common grades (Grade 5/Class 8.8 and Grade 8/Class 10.9) for quick repairs and maintenance.

By following these steps, you’ll reduce the risk of bolt failure and extend the service life of your assemblies.

Related Topics and Next Steps

- Bolt Coatings and Corrosion Resistance

- Understanding Thread Pitch and Diameter

- Stainless Steel vs. Alloy Steel Bolts

- How to Read Fastener Specification Sheets

- Best Practices for Bolt Re-Torquing and Inspection

Diving into these topics will deepen your mastery of fasteners and help you tackle complex projects with confidence

Mastering bolt grades is a small but critical piece of the engineering puzzle. With the right knowledge, you’ll select, install, and maintain fasteners that stand up to the toughest conditions. Keep “Bolt Grades” top of mind whenever you bolt materials together—your safety and success depend on it!