The Fundamentals of Liquid-Liquid Extraction

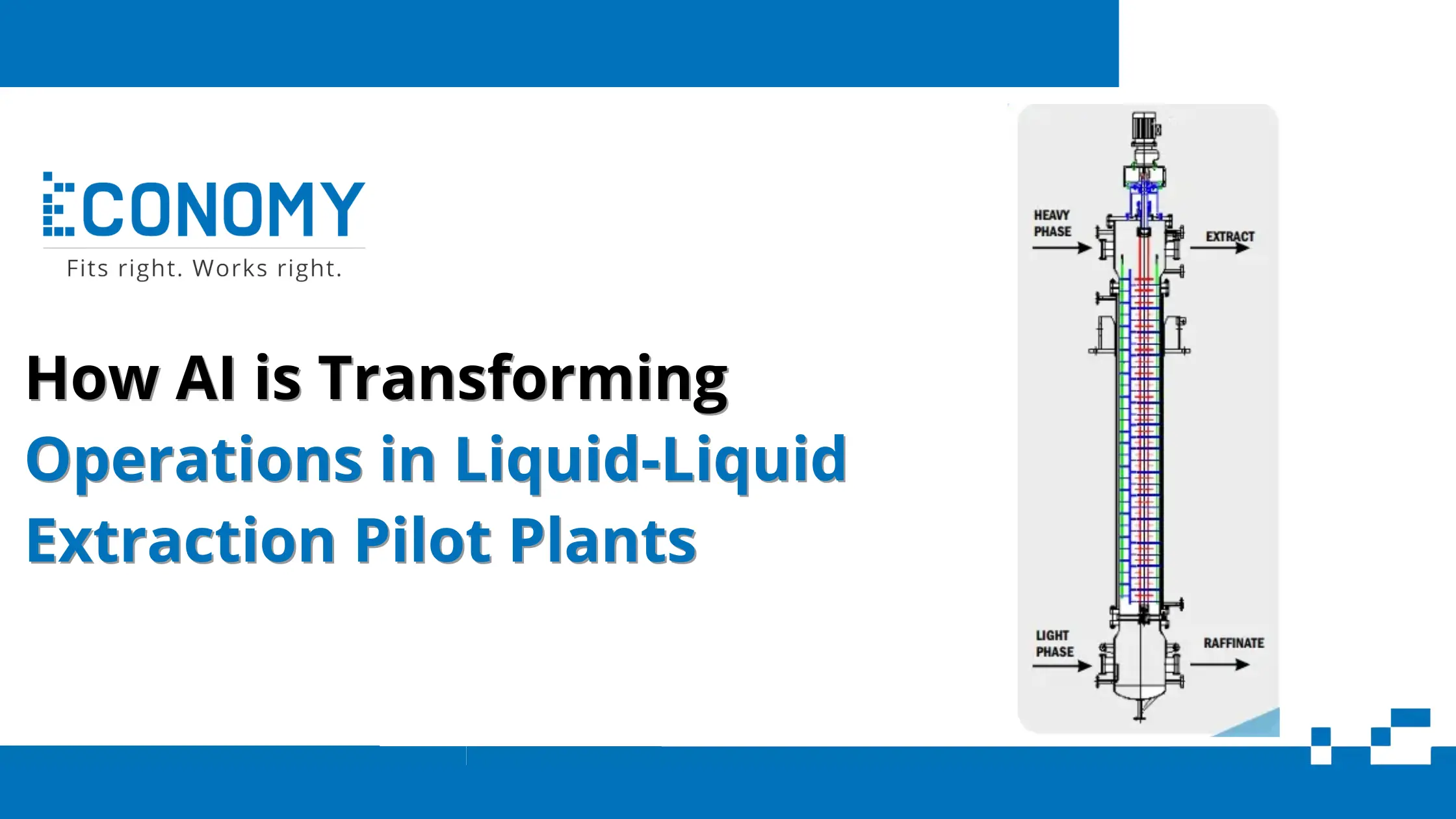

Liquid-Liquid Extraction (LLE) is a critical separation process used in industries such as pharmaceuticals, petrochemicals, and environmental engineering. It involves the transfer of a solute from one liquid phase to another immiscible liquid phase based on differences in solubility. Typically, one liquid is aqueous while the other is organic, and the solute of interest selectively migrates to one of these phases. The efficiency of extraction depends on several parameters—such as phase ratios, temperature, mixing intensity, and solvent selection—making the process highly sensitive and complex to control.

In pilot plants, LLE systems are used to develop and optimize extraction conditions before scaling up to full production. However, the manual monitoring and control of parameters can be time-consuming and prone to error. This is where Artificial Intelligence (AI) is emerging as a game-changer, offering data-driven precision, predictive insights, and operational optimization.

Artificial Intelligence in Extraction Process and Its Role

AI refers to the use of computational algorithms that mimic human intelligence to analyze data, make predictions, and optimize outcomes. In Liquid-Liquid Extraction, AI algorithms—such as machine learning (ML) and neural networks—can analyze vast amounts of process data to identify hidden patterns and relationships among variables.

For instance, AI can predict phase separation times, optimize solvent composition, and recommend suitable mixing intensities based on real-time data. Machine learning models trained on historical pilot plant data can forecast process behavior under varying conditions, reducing experimental time and improving accuracy. Moreover, AI-based control systems can adjust operational parameters dynamically, ensuring the process remains within optimal efficiency and safety limits.

AI also facilitates the use of digital twins—virtual replicas of the extraction system that simulate the process in real-time. These models can test various scenarios without disrupting the actual pilot plant operations, helping engineers make better decisions regarding process design, optimization, and troubleshooting.

Benefits of Executing Artificial Intelligence Innovation

The integration of Artificial Intelligence in Liquid-Liquid Extraction pilot plants offers a wide range of advantages:

- Enhanced Process Efficiency: AI algorithms optimize process parameters such as solvent ratio, mixing speed, and temperature to achieve maximum extraction yield with minimal waste.

- Reduced Operational Costs: Automated control and prediction reduce the need for repeated experimental trials, saving both material and energy costs.

- Data-Driven Decision Making: AI transforms raw sensor data into actionable insights, enabling process engineers to make informed adjustments rather than relying on manual trial-and-error methods.

- Improved Safety and Reliability: Predictive maintenance powered by AI helps detect anomalies or potential equipment failures early, reducing downtime and enhancing operator safety.

- Scalability and Consistency: By providing a precise understanding of process dynamics, AI ensures consistent results when scaling from pilot to industrial production.

- Faster R&D and Process Optimization: AI shortens development cycles by identifying optimal process configurations more quickly than traditional experimentation.

Contextual Analyses of Artificial Intelligence Execution in Extraction Frameworks

Several industries have already demonstrated the practical benefits of AI implementation in extraction processes.

In the pharmaceutical sector, AI-based predictive models have been used to optimize the extraction of active pharmaceutical ingredients (APIs). By analyzing real-time data from pilot-scale operations, these models improved solvent selection and phase equilibrium predictions, reducing development time by nearly 40%.

In the chemical and petrochemical industries, companies are using AI-driven control systems to enhance separation efficiency in multi-component extraction processes. Neural network-based models continuously learn from process data, enabling adaptive control and minimizing human intervention.

Similarly, environmental engineering applications have utilized AI to improve pollutant extraction from wastewater. Here, AI systems predict solvent performance and extraction kinetics, leading to better separation of contaminants and improved environmental compliance.

These real-world examples highlight how AI transforms traditional LLE processes into intelligent, self-optimizing systems that improve both performance and sustainability.

Overcoming Barriers to AI Adoption in Pilot Plants

Despite its potential, integrating AI into pilot plant operations comes with certain challenges.

- Data Quality and Availability: Reliable AI models require large datasets for training. However, many pilot plants lack consistent, high-quality data due to limited sensor integration or manual recording practices.

- High Implementation Costs: Installing advanced sensors, developing algorithms, and training personnel can be costly for smaller facilities.

- Resistance to Change: Operators accustomed to manual control may resist automation, perceiving AI as a threat to their traditional roles.

- Integration Complexity: Existing pilot plant setups often run on legacy systems that are not compatible with modern AI solutions.

- Skill Gaps: The effective use of AI demands expertise in both process engineering and data science—a combination that is still developing in many organizations.

To overcome these barriers, pilot plants can adopt a phased approach—starting with small-scale AI integration, building reliable datasets, and gradually expanding capabilities. Training staff and fostering collaboration between process engineers and data scientists are also critical for long-term success.

What Lies Ahead for Simulated Intelligence in Pilot Plant Tasks?

The future of AI in liquid-liquid extraction pilot plants is promising. Emerging technologies like edge AI, Internet of Things (IoT), and reinforcement learning are expected to enhance real-time process control and predictive accuracy further. As computing power grows and sensor technologies become more affordable, even small and mid-sized facilities will benefit from AI integration.

Moreover, combining AI with automation and robotics could lead to fully autonomous pilot plants—capable of self-monitoring, self-adjusting, and self-learning—paving the way for a new era of intelligent manufacturing and process optimization.

Final Words

Artificial Intelligence is reshaping how liquid-liquid extraction pilot plants operate, making processes more efficient, reliable, and intelligent. By leveraging real-time data and predictive analytics, AI enhances decision-making, accelerates process development, and ensures consistency in results. While challenges exist in implementation, the long-term benefits far outweigh the obstacles. As industries continue to embrace digital transformation, AI will play a pivotal role in revolutionizing separation technologies and driving innovation in pilot-scale extraction operations.